Gas Sensing

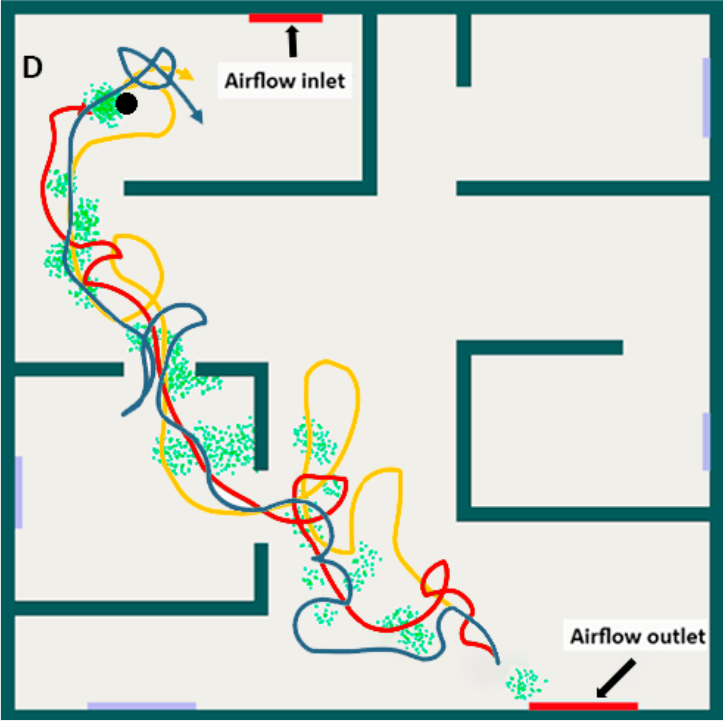

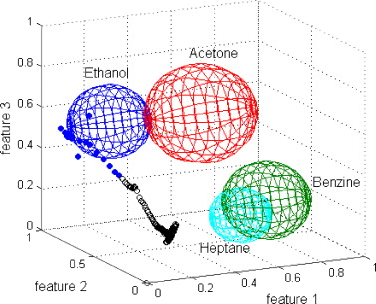

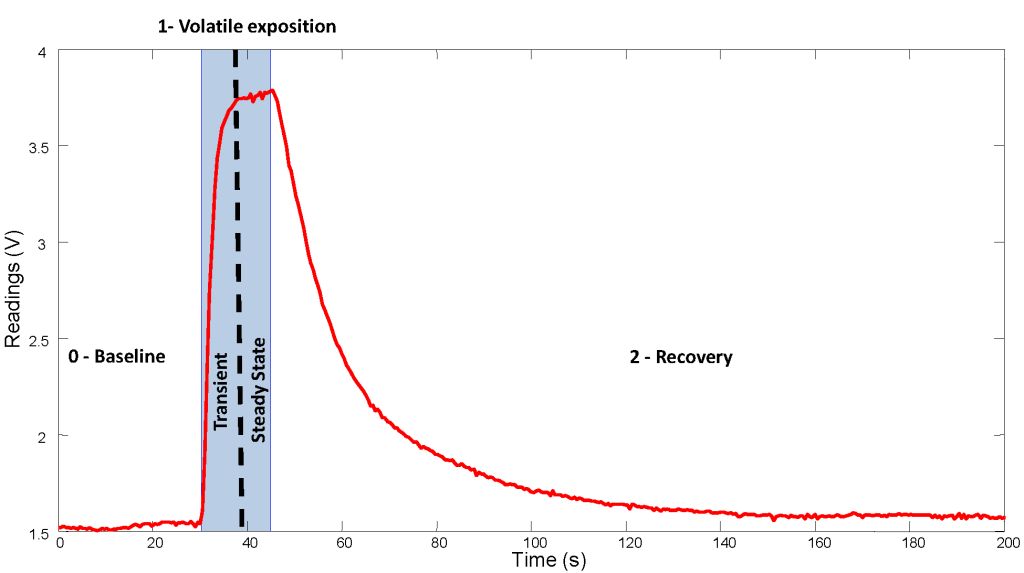

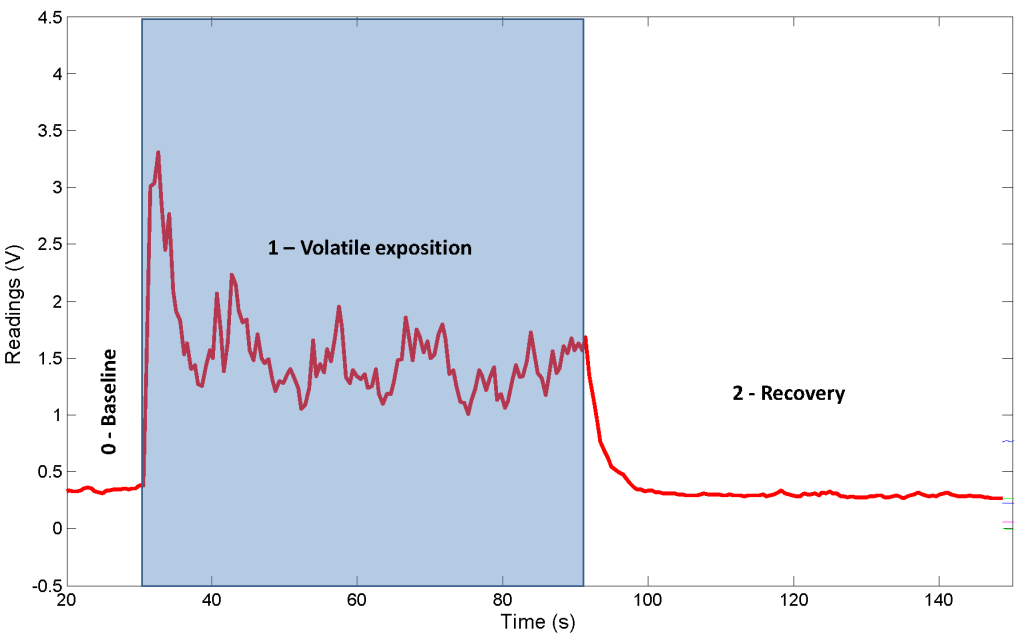

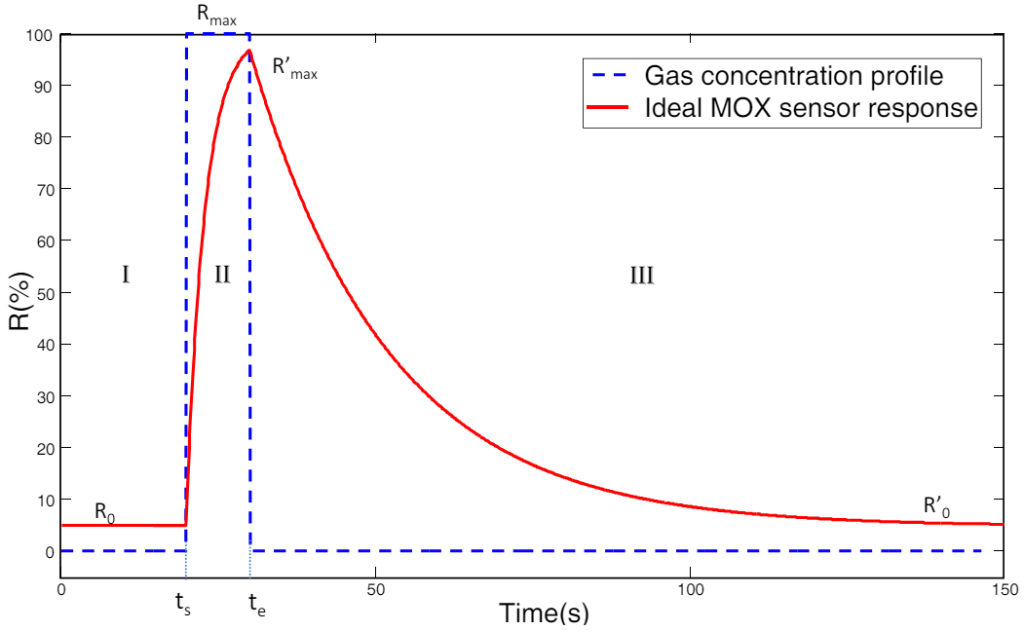

Gas sensing is the task of detecting volatile substances and providing conversion of that information into a signal or electrical magnitude readable by an operator or instrument. In the field of artificial olfaction, devices that fulfill this task are known as Electronic Noses (e-nose). E-noses are devices conceived to detect and monitor the concentration and composition of volatile substances, employing an array of non-selective gas sensors and some kind of pattern recognition algorithm. Their exploitation can be classified into two main categories according to the level of control over the measurement conditions: Closed Sampling Systems (CSS), where gas sensors are usually hosted in test chambers with controlled airflow, volatile exposure times, temperature and humidity, etc., and Open Sampling Systems (OSS), with no control over the sensing conditions. Our interest is in the latter, which are more flexible and practical for field applications, especially when accomplished with the help of a mobile robot carrying the e-nose on board, which makes the sensing task even more challenging. To illustrate the important differences in the signals collected when working with CSS or OSS, the figure below shows an example of the readings of an e-nose carrying one gas sensor.

We are actively working on the development of new approaches (Hw and Sw) to improve the detection of volatile substances with mobile robots. Particularly, we have studied and proposed different approaches to overcome one of the main drawbacks of metal oxide gas transducers (MOX) when used on OSS, their slow recovery (as can be appreciated in the previous figure).

Contents

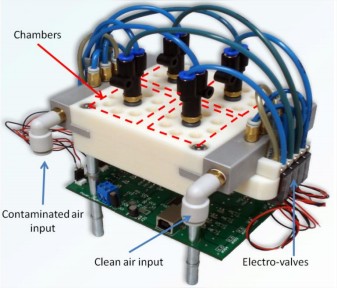

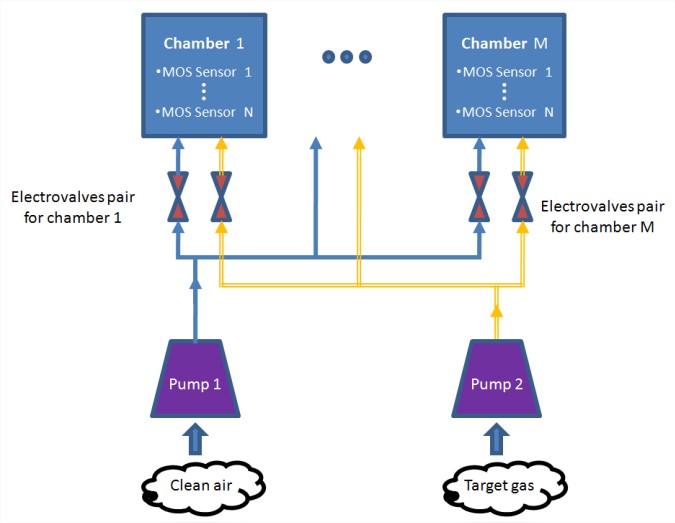

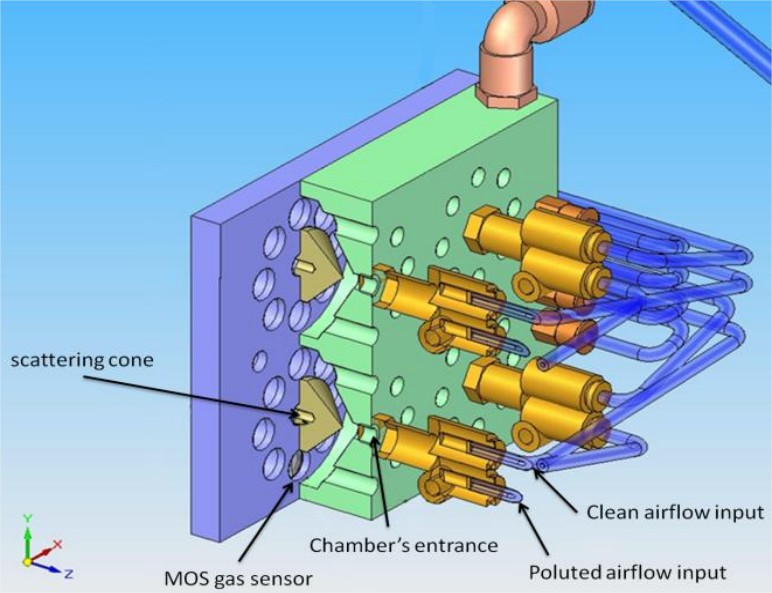

The Multi-Chamber E-nose (MCE-nose)

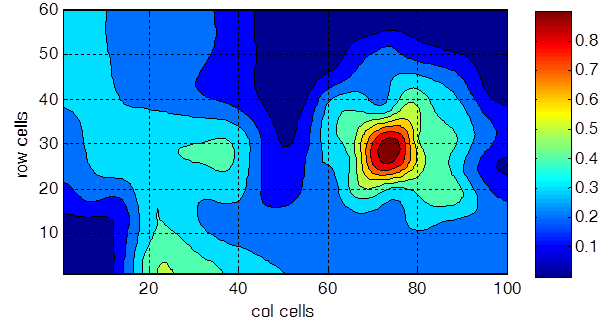

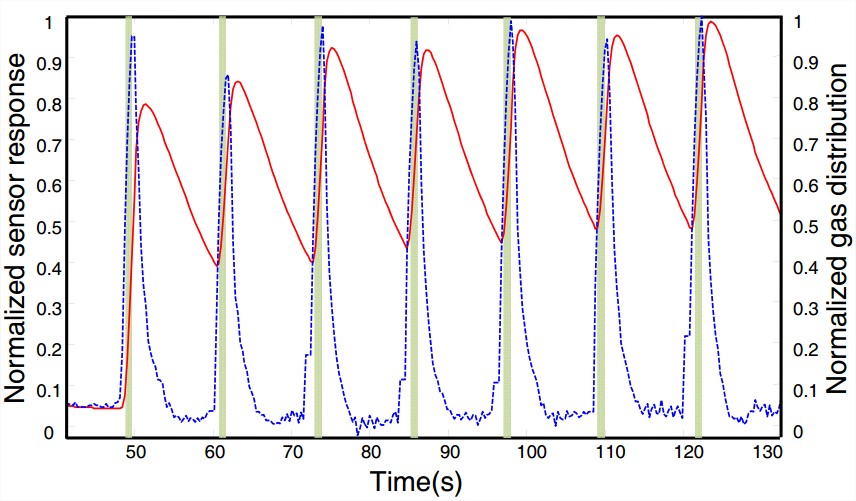

The MCE-nose is a novel design of e-nose that overcomes, to a great extent, the important limitation of the “slow recovery” of gas sensors. The proposed MCE-nose comprises several identical sets of metal oxide (MOX) transducers accommodated in separate chambers, which alternate between sensing and recovery states, providing, as a whole, a device capable of sensing changes in chemical concentrations faster. The utility and performance of the MCE-nose has been shown through several experiments involving the sensing of volatile substances featuring rapid changes in concentration, and the generation of gas distribution maps with mobile robots (see Publications below).

The MCE-nose pretends to work similarly to wine testers but takes advantage of the reproducibility of electronic devices to avoid the downtime between readings. Thus, the key idea behind the proposed design is to ignore the gas sensor array output when the decay phase is detected and delegate the sensing task to another clean, almost identical array of sensors. To achieve that, we accommodate a set of redundant sensors in different chambers, which are alternatively activated. Thus, the output signal of the whole setup results from the concatenation of the rise phases of a sequence of MOX sensor arrays. For further details and evaluation of this device, please refer to the Publications section below.

Overcoming the Slow Recovery of Gas Sensors Through a System Modeling Approach

MOX gas transducers are one of the preferable technologies for building electronic noses because of their high sensitivity and low price. They present, however, several drawbacks as their long recovery times (tens of seconds), which limits their suitability to applications where the e-nose is exposed to rapid changes in the gas concentration. To overcome to a certain extent this important disadvantage, this approach proposes exploiting a double first-order model of the MOX-based transducer from which a steady-state output is anticipated in real-time given measurements of the transient state signal.

The applicability of the proposed approach is validated with several experiments in real, uncontrolled scenarios with a mobile robot bearing an e-nose. Furthermore, it is proved that this approach enables a considerable increase in the speed at which a mobile base carrying the MOX-based e-nose can inspect the environment, which directly implies an important reduction in the execution times of the olfaction task. For further details on the equations governing the model and results, please refer to the Publications section below.